FMEA (Failure Mode and Effects Analysis) is a method created by US military and has become a standard in the automotive sector, especially when it comes to security relevant components.

There are two main approaches in FMEA: focusing on functions (Product-FMEA) and focusing on processes (Process-FMEA).

FMEA means analyzing systems and risks during development and product planning. It contains both system optimization and risk minimization. FMEA helps to detect possible failures and prohibit occurrence of failures at an early stage. FMEA is used for new concepts as well as development and advancement of products and processes. Risks that have their causes in those possible failures are getting evaluated, tasks to avoid those failures are getting developed.

DRBFM

DRBFM

Design FMEA

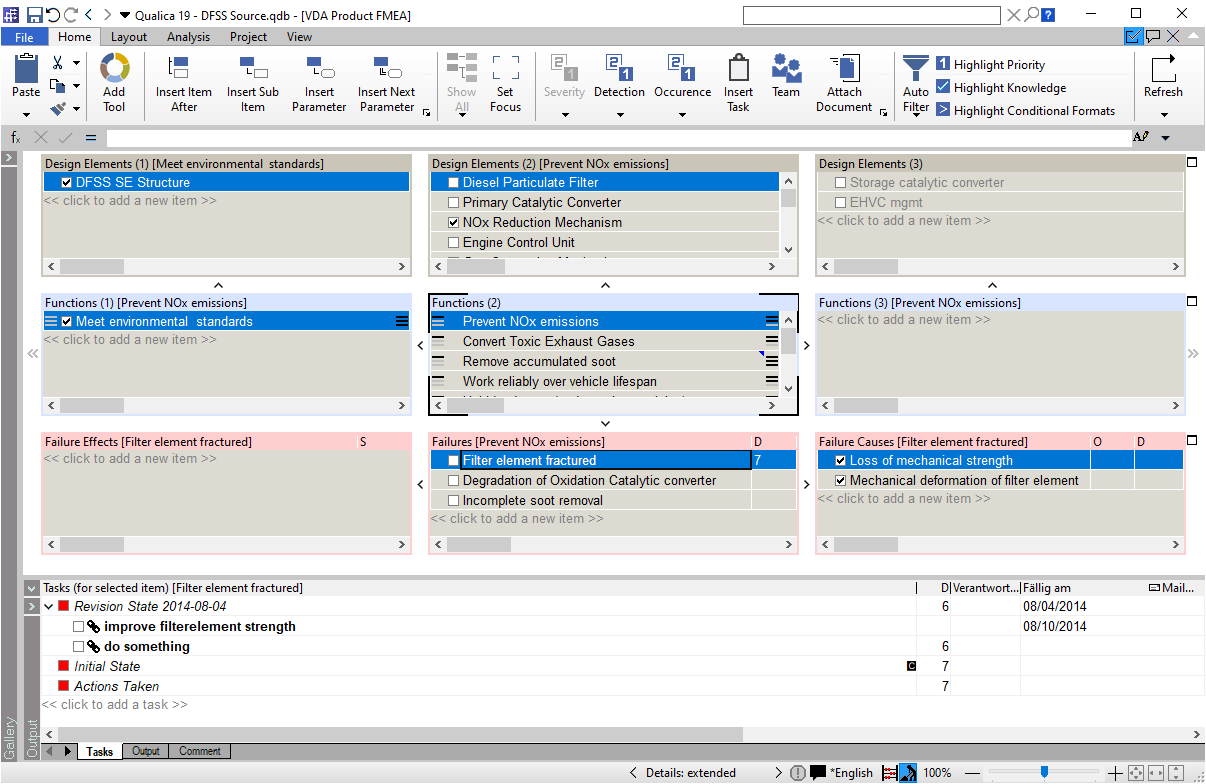

Qualica Software provides a specialized form for editing system, functions, and failures in one view. Of course, the <i>System Analysis</i> component can also be used to define the structure in a graphical way.

Process FMEA

Product FMEA VDA Standard

Fault Tree Analysis

The fault tree component in Qualica Software is derived from the tree diagram.